The Evolution of Ecotron’s TCU Controller: From ET22367A02 to ET82367A

As vehicle technology rapidly evolves, OEMs and system integrators face the challenge of selecting control units that match their platforms’ performance goals, architecture strategies, and long-term adaptability. At Ecotron, we offer multiple solutions to meet a wide range of needs; each designed to optimize specific control domains while providing flexibility and scalability.

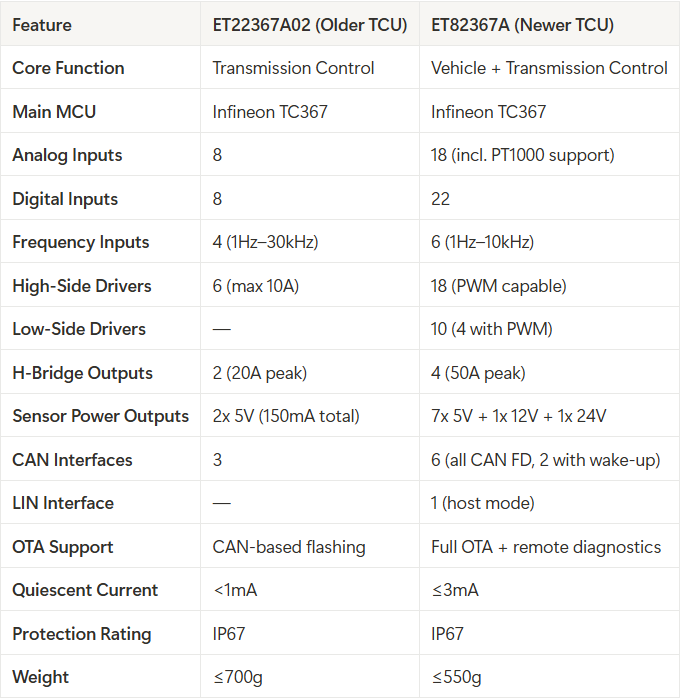

Two of our flagship products, the newer ET82367A Transmission Control Unit (TCU) and the older ET22367A02 Transmission Control Unit (TCU), reflect this goal. While both deliver robust and reliable performance, they serve different design objectives and are ideal for distinct use cases. Choosing between them depends not on which is “better,” but on which is best aligned with your platform requirements.

The ET82367A represents a new direction in vehicle control. Designed for modern, centralized E/E architectures, the new TCU integrates both vehicle-level and transmission-level control into a single module. This consolidation simplifies wiring, reduces hardware costs, and improves real-time coordination across powertrain domains. The ET82367A supports a broader range of inputs and outputs—18 analog channels, 22 digital inputs, six frequency inputs, 18 high-side and 10 low-side drivers, and four powerful H-bridge outputs rated up to 50 amps peak. It also includes enhanced capabilities for vehicle energy management, intelligent drive modes, and remote diagnostics through OTA update support. Remarkably, despite its broader functionality, the ET82367A is slightly more affordable due to the efficiency gains from integrating multiple control domains.

In contrast, the ET22367A02 is a mature, high-performance TCU focused on dedicated transmission control. It is well-suited for platforms that operate within a traditional distributed electronic/electrical (E/E) architecture. With eight analog inputs, eight digital inputs, high-side drivers capable of up to 10 amps, and dual H-bridge outputs for motor actuation, this unit excels in precision-driven applications where the transmission controller must operate independently and reliably. Its robust diagnostics, optional gyroscope, and 1 mA quiescent current make it a dependable solution for both ICE-based and electrified systems where a separate VCU already exists.

While the TCU remains the preferred choice for projects requiring independent subsystem design, the newer TCU is a compelling option for those pursuing integrated, software-defined platforms. It supports the needs of next-generation electric vehicles and connected architectures, providing features like CAN FD communication, LIN support, real-time torque coordination, and built-in gyroscopic sensing for enhanced vehicle dynamics.

The decision between these two controllers comes down to application needs. For modular vehicle architectures or projects that already incorporate a VCU, the ET22367A02 delivers proven reliability, high configurability, and seamless integration with existing CAN-based networks. For centralized vehicle platforms aiming to reduce latency and increase computational efficiency, the ET82367A offers advanced integration, broader I/O capability, and the ability to serve as both a transmission and vehicle controller in one unit.

Both controllers are engineered to meet Ecotron’s high standards of quality, protection (IP67 rated), and compliance with ISO and ECE-R10 EMC and environmental test standards. Each supports extensive software tools, including EcoCoder, EcoFlash, and EcoCAL, ensuring that customers can develop and deploy their vehicle logic efficiently. Whether you are building a next-generation electric SUV or upgrading a specialized commercial drivetrain, we have the right control solution to help you get there—with flexibility, performance, and value in mind.

Still Unsure? We Can Help.

Every project is unique, and we are here to help you make the right technical and commercial decision. Reach out to our team at info@ecotron.ai or visit www.ecotron.ai to learn more about integration support, software tools, and application examples.