Evaluating Ecotron’s Autonomous driving domain controller design through the clash of three kingdoms: Nvidia, Huawei, and Tesla

1. Introduction

Since my first encounter with NXP’s S32V234—the BlueBOX—I have been involved in the design of autonomous driving domain controllers. Later, I learned about NVIDIA Jetson TX2, NVIDIA Drive PX2, NVIDIA Xavier, etc., and from other sources, I learned about ZF ProAI, ZFAS, Mobileye, Renesas, Huawei, etc. Our domain controller architecture was likewise based on Xavier because the information we had was not particularly precise and the most of our efforts were devoted to the creation of NVIDIA Xavier.

The core of smart driving vehicle control is the autonomous driving domain controller, also known as the smart driving domain controller. The domain controller connects sensors like cameras and LIDAR, network communication elements like V2X and combined navigation, and the wired control unit of the vehicle. It is primarily in charge of processing environmental information gathered by the sensors for fusion, identification, and classification, along with map positioning for path planning and driving decision-making, in order to achieve precise control of the vehicle and automatic driving.

You can quickly review the fundamental design principles of domain controllers by looking at a few typical domain controller products, such as Tesla FSD HSW3.0, NVIDIA Driver, Huawei MDC, etc.

2. Typical domain controller design analysis

2.1 Tesla HW3.0

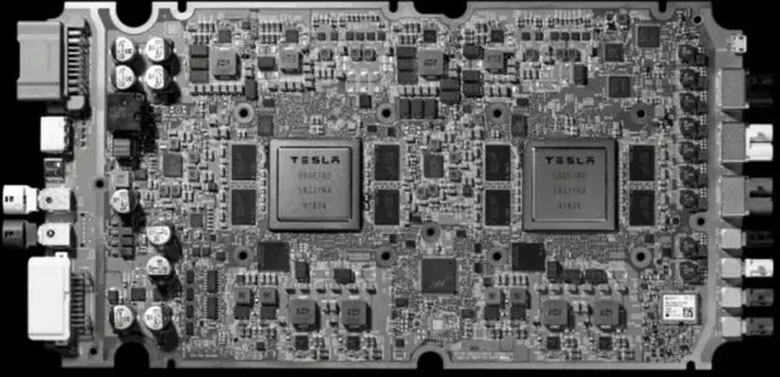

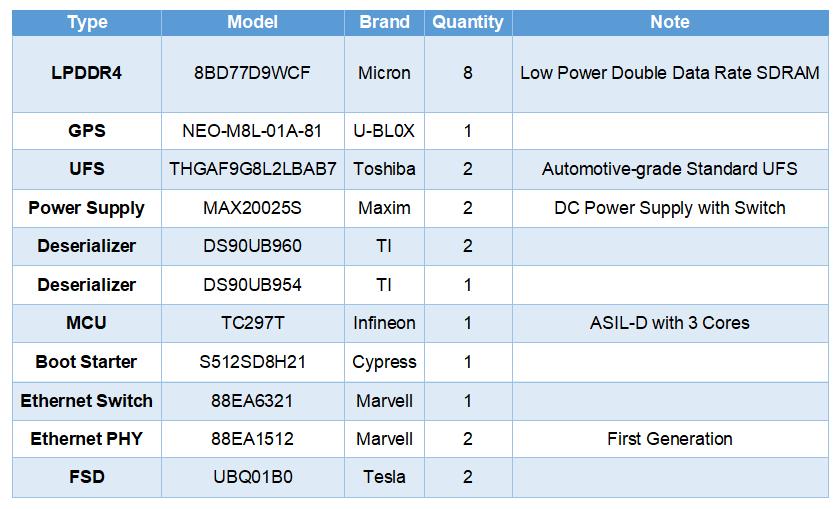

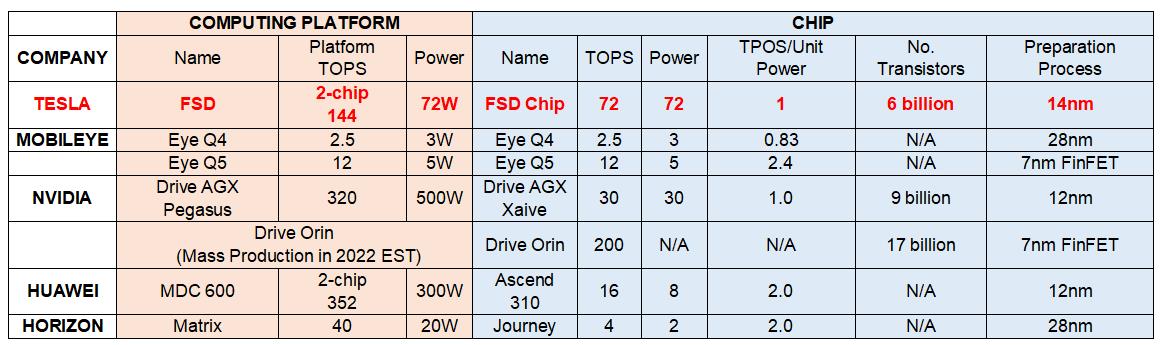

Although its hardware composition has been examined before, not much is known about Tesla’s own unique domain controller. For a total of 4 x 36 Tops of processing power (144 Tops), FSD’s HW3.0 comprises of two identical computing units, each with two of Tesla’s own FSD computing chips, each with 36 Tops of computing capacity. However, the actual computing power is 72 Top because of the two-machine redundancy thermal standby operation. The following table shows the hardware components of HW3.0.

The FOV camera, surround view camera, A-pillar left and right camera, B-pillar left and right camera, front view main camera, in-car DMS camera, rear camera, and GPS coaxial antenna are all located on the right side of the Tesla board, in that sequence. The second power supply and I/O interface (body LIN network, etc.), Ethernet diagnostic in/out, debug USB, burn-in, primary power supply and I/O are located on the left side from top to bottom (chassis CAN network, etc.).

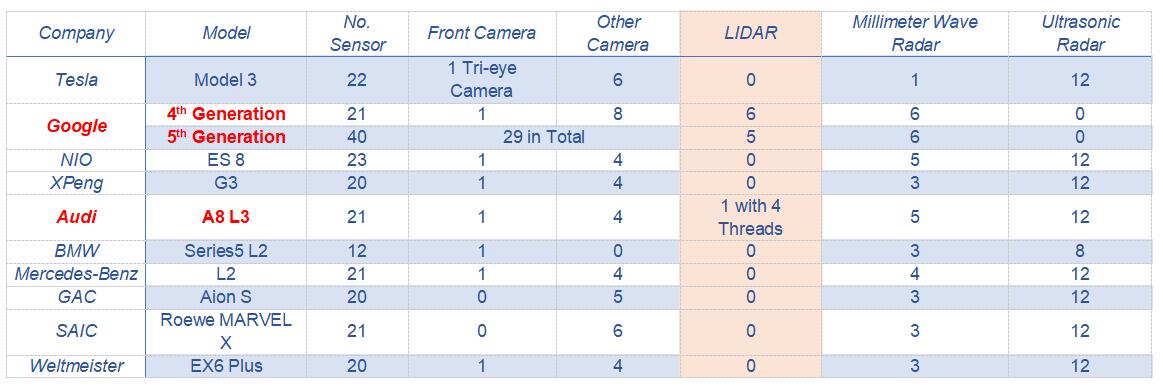

Advocating camera vision as the core of the Tesla installed a trinocular camera, four surround view, a rear camera, in-car DMS camera, front millimeter wave radar, and 12 ultrasonic radar. This was done through the presentation and actual configuration of Tesla’s models on sale.

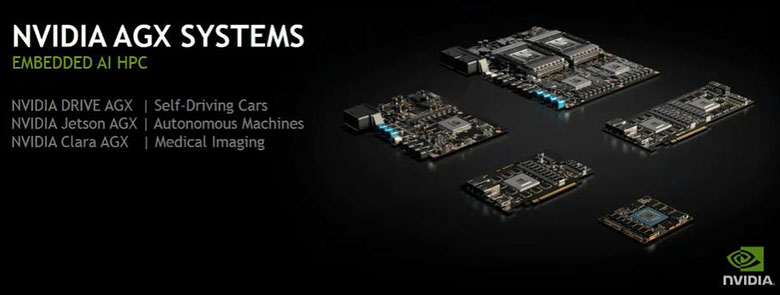

2.2 NVIDIA Driver AGX Xavier

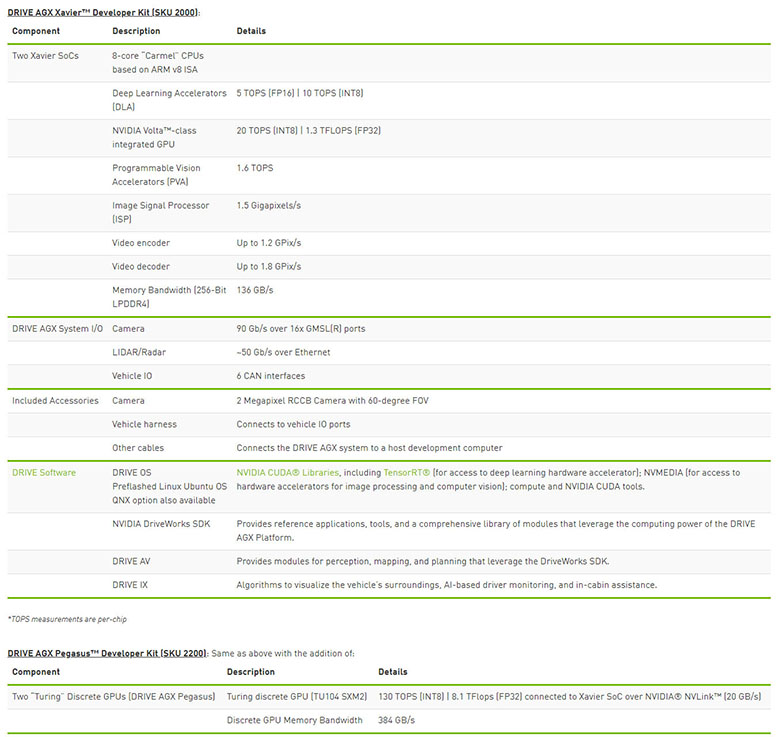

NVIDIA DRIVE AGX Xavier™ delivers 30 trillion operations per second (TOPS) for L2+ and L3 autonomous driving. At its core is NVIDIA’s first automotive-grade Xavier system-on-chip, which features six different types of processors, including CPU, GPU, deep learning gas pedal (DLA), programmable vision gas pedal (PVA), image signal processor (ISP) and stereo/optical flow gas pedal.

NVIDIA DRIVE AGX Pegasus™ uses the power of two Xavier system-on-chips and two NVIDIA Turing™ GPUs to achieve a higher than ever 320 TOPS of supercomputing power. The platform is designed and built specifically for L4 and L5 autonomous systems, including robotic cabs.

2.3 NVIDIA Jason Xavier

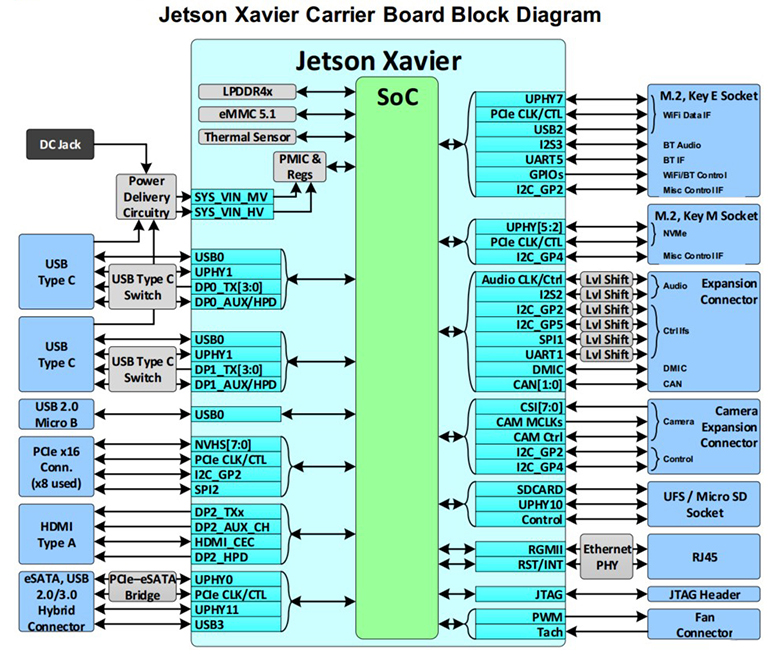

According to the parameter sheets for the NVIDIA DRIVE AGX XAVIER and PEGASUS as well as the physical images above, the NVIDIA DRIVE offers 16 GMSL camera inputs, an Ethernet interface, six CAN bus interfaces, and connections for vehicle I/O.NVIDIA Jetson Xavier

The NVIDIA DRIVE series platforms all use Xavier chips with 30Tops of computing power. Since automotive-grade Xavier modules are not easily available, some research and development has been done using the Jetson Xavier kit.

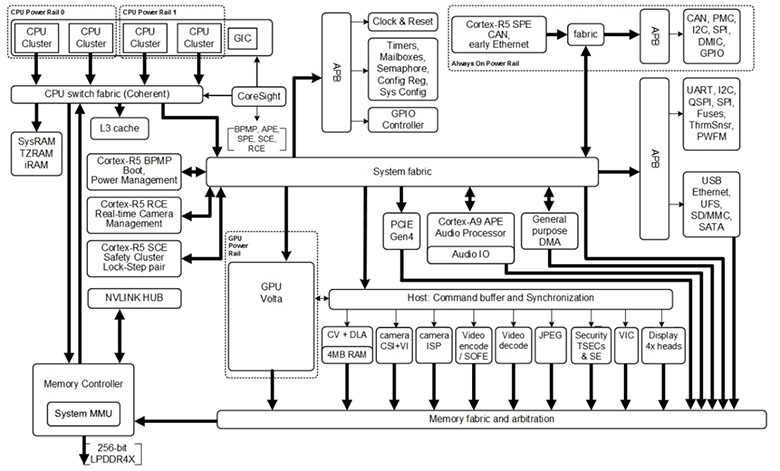

The Xavier chip integrates 9 billion transistors, the CPU is powered by NVIDIA’s own 8-core ARM64 architecture (codenamed Carmel), the GPU is powered by 512 CUDA Volta, and it supports FP32/FP16/INT8 and has a single-precision floating point performance of 1.3TFLOPS at 20W power consumption as well as 20TOPs for the Tensor core and up to 30TOPs after unlocking to 30W. Inside Xavier are six separate processors: an octa-core ARM64 CPU, dual NVDLA deep learning gas pedals, an image processor, a vision processor, and a video processor. Valta TensorCore GPU is also included.Xavier

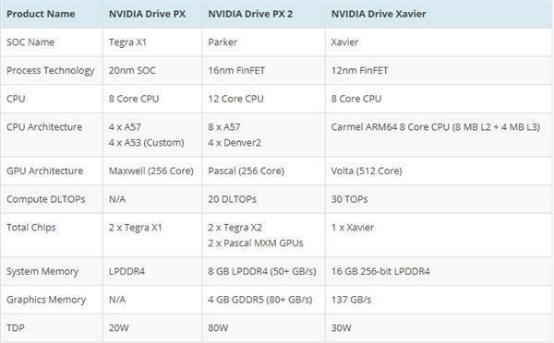

In terms of arithmetic power and performance, Xavier significantly outperforms earlier NVIDIA platform generations. This can be shown by comparing the tables below.

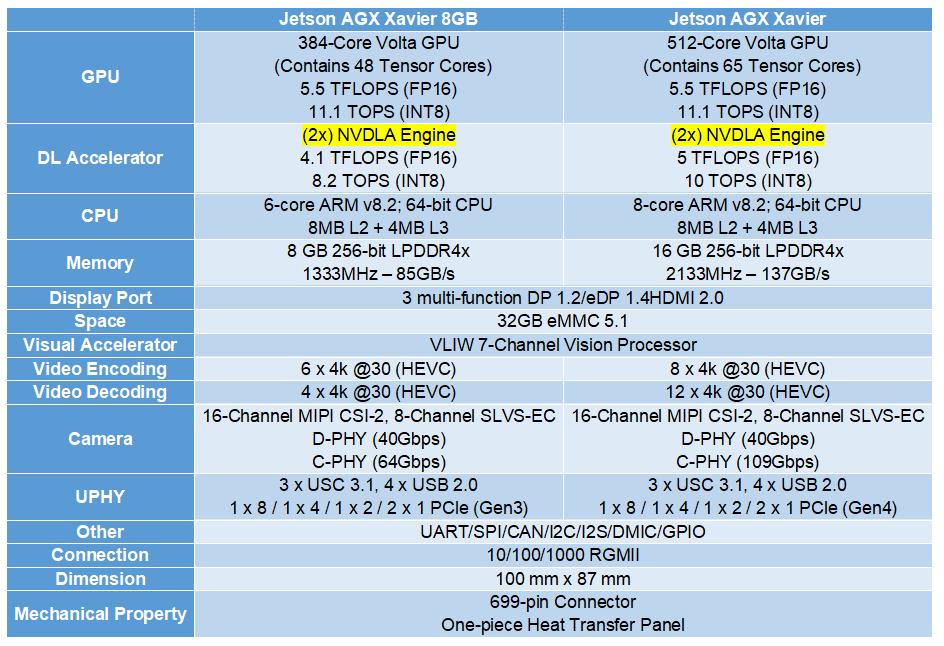

Jetson AGX Xavier 8GB and Jetson AGX Xavier are the two variants of Xavier that are offered to meet the varying development needs of clients.

With up to 32 TOPS of computing power to act as the core of L3-level domain controllers, Jetson AGX Xavier is the undisputed market leader in autonomous driving and one of the few domain controller development platforms that are ready for mass production. This platform performs algorithm operations like environment sensing, path planning, and intelligent control decisions. Additionally, NVIDIA’s broad ecosystem enables developers to create AI algorithms and carry out relevant training swiftly thanks to its rather comprehensive AI tools and process.

The Jetson AGX Xavier 8GB is a low-cost, fully compatible replacement for the original Jetson AGX Xavier in terms of both hardware and software. While providing up to 20 TOPS of AI computational power, its complete module can use up to 20W of power. The table below provides a comparison of the Jetson AGX Xavier 8GB and Jetson AGX Xavier.

2.4 HUAWEI MDC

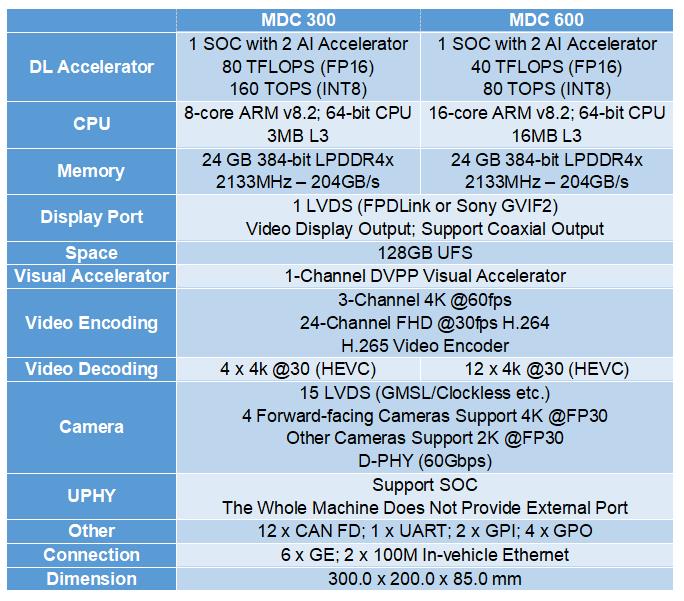

The MDC intelligent driving computing platform was introduced by Huawei in 2018 along with a full-stack solution for high-level autonomous driving. These platforms include the MDC300 and MDC600, which correspond to L3 and L4 levels of autonomous driving, respectively, and are likely to be outfitted with the Hongmeng kernel operating system in addition to the intelligent driving AI algorithms. The final form will be a vehicle-grade mass-producible domain controller.

The MDC600 is based on eight Rise 310 AI chips, and it also integrates the CPU and corresponding ISP module, with an arithmetic power of 352TOPS. The MDC300 is composed of Huawei’s Rise 310 chip, Huawei’s Kunpeng chip, and Infineon’s TC397, with an arithmetic power of 64Tops to meet the arithmetic power requirements of L3 level autonomous driving.

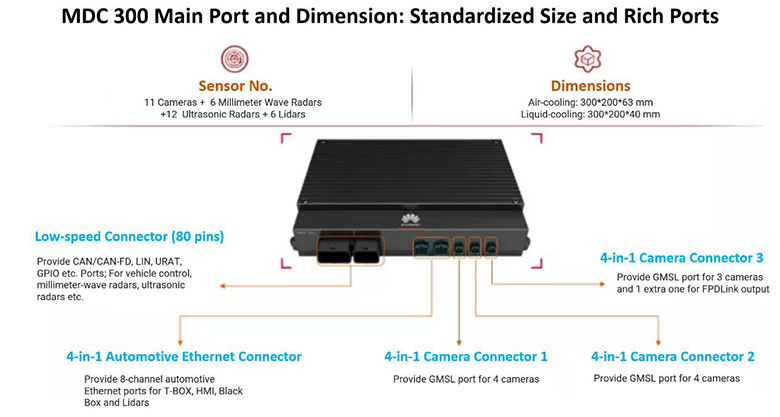

Huawei MDC provides 15 LVDS camera input interfaces, 12 CANFD buses, 6 general Ethernet, 2 100 Gigabit on-board Ethernet, and multiple GPIOs.

The main benefit of Huawei MDC over competing platforms is the ease with which its unified system design allows for functional growth and scenario adaption. In addition, Huawei MDC exhibits the traits of component service, interface standardization, development tooling, and driving applications as an open platform.

3. Domain controller design requirements

As mentioned at the beginning of this paper, the autonomous driving domain controller, or intelligent driving domain controller, is mainly responsible for fusing, identifying and classifying the environmental information sensed by sensors, and making path planning and decision on vehicle driving in combination with map positioning, so as to achieve precise control and automatic driving of vehicles.

Therefore, the domain controller as an intelligent hardware, in order to complete complex AI computing and intelligent control, the hardware level needs AI processing chip that undertakes super large computing power requirements such as environment perception and deep learning, CPU that is responsible for control decision and logic operation, and MCU that is responsible for functional safety and vehicle control; the software level includes operating system, middleware, and application layer AI algorithm, etc.

Three significant chips, or three components of the hardware level chip includes: The first component is typically a GPU or TPU, which meets the demand for large-scale floating-point parallel computing and is primarily used for environment perception and information fusion, including the recognition, fusion, and classification of sensor information such as camera and LIDAR, as in the case of Xavier’s GPU unit and the Rising 310.

The second section mostly consists of ARM architecture, which is analogous to a CPU and is used for logic operations and decision-making, including processing high precision floating point serial calculations.

The third component, which is primarily in charge of reliability and vehicle management and plays a functional safety and redundancy monitoring role, does not call for a lot of computational power, but the dependability must be guaranteed. At the moment, Infineon’s TC297 or TC397 is most frequently utilized.

Application layer at the software level Middleware is typically provided by the domain controller developers, similar to ROS, and primarily contains some interface drivers for the optimization of the operating system deployment. AI algorithms are typically developed by the car-making enterprise or host plant themselves, which is reflected in the performance of the vehicle and the poor. Huawei use its own Hongmeng operating system, and the MDC platform is compatible with Adaptive AUTOSAR; QNX is currently the best and only choice for vehicle specification, but faces high costs; Linux and Autoware have gained the most users due to open source, especially Linux, which is currently very popular based on the Linux kernel with its strong engineer base and ecology, coupled with the multi-year application base of ROS.

The strength of a domain controller resides in its interface resources in addition to the hardware and software level. Before summing, take a look at the comparison of the interfaces from various manufacturers for autonomous driving systems that is provided after mentioning the interface resources of Tesla HW3.0, NVIDIA Driver series, NVIDIA Xavier, and Huawei MDC.

Comparative investigation has revealed that although there are many sensors used in autonomous driving systems, the types are limited to cameras, LIDAR, millimeter wave radar, ultrasonic radar, integrated navigation, IMU, V2X modules, etc.

There are not many possibilities for autonomous driving systems for cameras; available interface types include MIPI SI-2, LVDS, GMSL, FPDLink, etc.; LIDAR use Ethernet interfaces, the majority of which are currently common; millimeter wave radar use CAN bus transmission; ultrasonic radar only need LIN bus; combined navigation and inertial guidance use RS232 serial ports as their common interface; and V2X module use Ethernet interface transmission.

The next presentation is a domain controller design solution from Ecotron’s Xavier. Currently very active in the market and generally favored NVIDIA Xavier-based domain controller design.

4 About AI chip selection

4.1 Selection of AI chips

There are only three manufacturers of AI processors now on the market: Tesla, NVIDIA, and Mobileye. This is especially true of those that have reached mass production. Other brands can currently obtain test samples through collaborative development in addition to Tesla’s self-research and self-use, which are not external.

There aren’t many firms developing domain controllers based on Xavier modules since, comparing to other platforms, NVIDIA Xavier was released earlier and has a pretty decent ecological structure, which allows developers to build systems and develop AI applications quickly.

The Xavier SoC, which can process up to 30TOPs of data, contains six different processors, including a Valta TensorCore GPU, an octa-core ARM64 CPU, dual NVDLA deep learning gas pedals, an image processor, a vision processor, and a video processor. This gives it the ability to process dozens of algorithms for path planning, localization and mapping, processing sensor data, and more simultaneously and in real time. The following figure shows the chip’s internal structure:

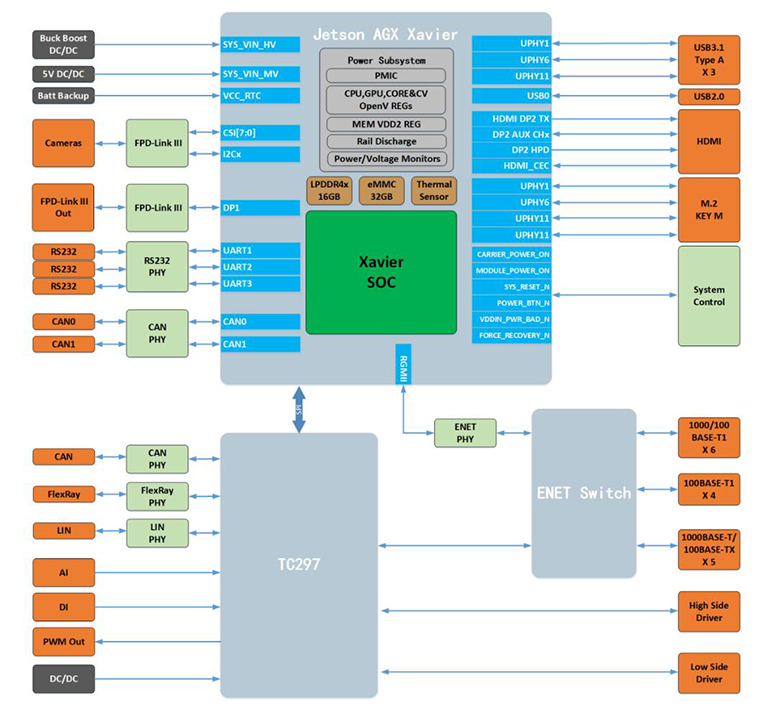

The core module Xavier from NVIDIA has the following interface.

4.2 Domain Controller Architecture Design

The domain controller model EAXVA04 has reportedly been installed in small batches and is the fourth version of the product. It is intended to be used with Infineon TC297T and NVIDIA Xavier during deployment. While TC297 is used for entire vehicle management, safety monitoring, redundancy control, and gateway communication, Xavier is utilized for environment awareness, image fusion, and path planning.

Although the controller is very large, the interface is extremely extensive, making it an entirely suitable programming platform.

| Port Type | Quantity | Notes | Chip |

| Camera Input | 8 | FPDLinkt III | SOC |

| Video Output | 2 | 1-channel HDMI, 1-channel FPDLink III | SOC |

| USB | 4 | 3-channel USB Host, 1 channel USB OTG | SOC |

| RS232 | 3 | 1 Channel for debugging | SOC |

| In-vehicle Ethernet | 10 | 6-channel 1000Base-T1 100Base-T1 Self-adaptive 4-channel 100Base-T1 | Switch |

| Gigabit Ethernet | 5 | Meet IEEE 100BASE-TX/IEEE 1000BASE-T Standard | Switch |

| CAN | 8 | 2-channel to SOC; 6-channel to MCU Support CAN FD | SOC + MCU |

| LIN | 2 | — | MCU |

| Flex Ray | 1 | — | MCU |

| DI | 26 | — | MCU |

| AI | 15 | — | MCU |

| LSD | 18 | 4-channel OPWM | MCU |

| HSD | 10 | 2-channel OPWM | MCU |

| 5V Power | 5 | — | MCU |

| PPS | 1 | Time Synchronization Signal | SOC + MCU |

Due to greater GPIO, the rich interface mentioned above may connect to 8-way cameras, multi-way LIDAR, multi-way millimeter wave radar, and other devices. This eliminates the need for a chassis controller altogether.

However, its power consumption is also very high, with two relatively powerful cooling fans and a more powerful heat output of 35W when additional GPIO is not practicable.

4.3 Software development

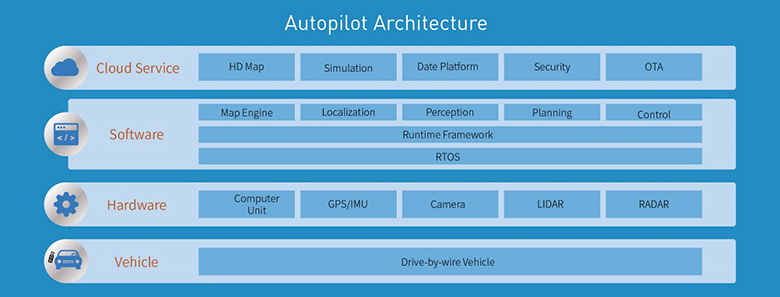

According to the instruction manual provided by Ecotron, the SOC software system of this domain controller, also known as Xavier part, is custom developed for autonomous driving system applications, and the software system includes RTOS, Runtime Framework and other parts. Among them, RTOS is Linux operating system and Runtime Framework is melodic version of ROS (Robot Operating System). As shown in the figure below.

It is highly advantageous for engineers who are familiar with Linux systems and ROS applications because creators of AI application algorithm can build on Linux systems or make pertinent ports of previously built software.

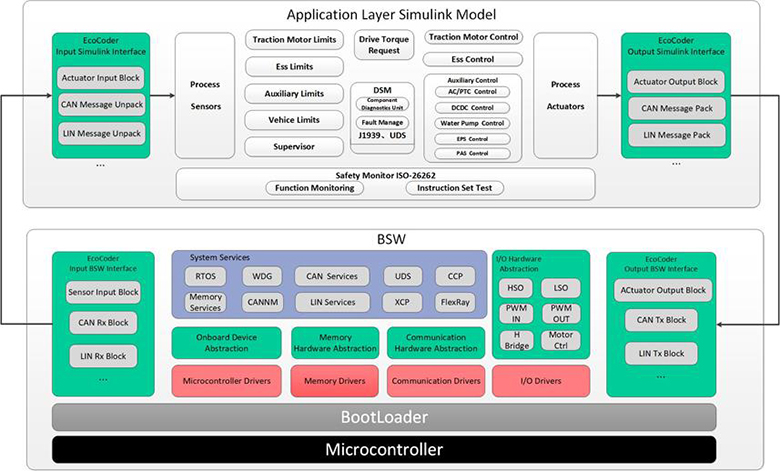

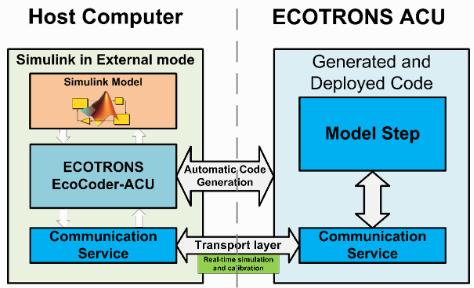

The domain controller’s TC297 MCU is divided into an application software layer and a basic software layer, and its software architecture was developed with regard to AUTOSAR. EcoCoder connects the application layer and the base program by encapsulating the base software interface in the Simulink module library using the s-function in Simulink. Developers can create an executable program file that is tailored to TC297 by Simulink with only one click using Simulink to develop the application layer model.

4.4 Software Toolchain

Ecotron offers the domain controller’s fundamental function bundle as well as its own in-house built development tools to make it easier for development users to use them. Users can create programs that are relevant to particular settings using the EcoCoder, EcoCAL, and EcoFlash programming tools for TC297 and the EcoSDK-XV, respectively, for Xavier.

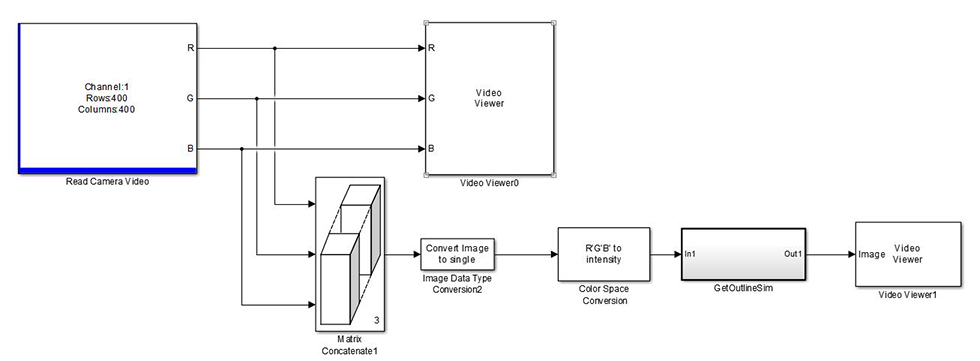

As a cross-compilation tool chain, EcoSDK-XV offers customers a full application development environment with a bundle that includes all the tools required for developing ROS-based apps for the Linux operating system.

EcoCoder-AI is a potent Matlab/Simulink-based automatic code generation library for SOC chips that may be attached directly to the target controller. Code creation, compilation, and one-click executable file production are all integrated by EcoCoder-AI. It has the ability to download the control model created on Simulink directly into a Linux-based executable software for the target controller. Although the application is imperfect and the library module is not entirely functional, this technology is the first of its kind in China and can perform some basic AI development, which is extremely uncommon.

When compared to the current efficiency of creating code while debugging, the domain controller of UCCW can be based on Simulink’s external mode to achieve real-time online calibration and debugging. However, due to Simulink’s own support and popularity, this function still need improvement.

EcoCoder, an automatic code generation tool for MCU development based on Simulink, EcoCAL, a professional calibration and debugging tool, and EcoFlash, a specialised brush writing tool, are three components of a rapid prototype tool chain created by Ucontrol for automotive electronic controllers.

5. Conclusion

Although the AI arithmetic chip’s technical bottleneck and the debate over chip technology architecture have always existed, the autonomous driving computing platform from the early IPC to the current domain controller does not deny that several brands of SOC and domain controller are still doing well, especially based on the development of chips like NVIDIA Xavier and pre-PX2. Most domestic businesses, notably new power vehicle manufacturers, are more focused on the Xavier platform and Linux system, whereas conventional automobile manufacturers choose TI, Renesas, and other semiconductor companies’ intelligent AI chips and QNX system.

There are numerous Xavier-based businesses worldwide, and Ecotron’s current domain controller products are in the medium to upper echelon of the industry, but our software tools and services are generally better.